Double-Actings Cylinders Hydraulic Guillotine Bale Cutter SMCM-014

* Double-acting hydraulic cylinders control

* High forming speed

* Rolls are made of chilled cast iron alloy ,cold-grinding surface,whose hardness reach up to 70HRC

* Equipped With Anti Friction Roller Bearings

* Single motor drives each calendering rolls

* Friction gear regulate the speed ratio seperately

* To guarantee the accuracy of calendered product, axis cross , pull-back and pre-bending device provided for rolls

* Highly efficient and Easy operation system

* Able to form at relatively low resin temperatures

* Precision calender with direct compression

* Temperature controllable, solid rollers made of special steel

* Width and thickness ranges for films are wide and control precision is high

* Profile control is simple, and film uniformity and dimensional precision are high

ooking for a machine that is reliable, efficient, and easy to operate? Look no further than the Two-roller rubber calender machine.

Calender machines are one of our specialties. These robust machines combine extremely high compression capability with precision.

This calendaring machine is specifically designed to roll out rubber sheets, making it an excellent choice for those who need to manufacture sheets for various applications. The rolls are made of chilled alloy cast iron, which ensures that they maintain their shape and durability even under extreme conditions. Additionally, the machine is equipped with various features that make it easy to use and navigate.

Calendering machine is a continuous process which adopt heated rollers that are fed with a pre-compounded paste-like mass. The rollers of calenders machine are made up of chilled cast iron with vanadium and titanium alloys, which are hard and anti-wear. These rolls are separately driven by DC motors, which allow you to adjust the speed range separately.

This two-roller rubber calender machine can efficiently used for calendering of rubber or plastics, fabric fraction and coating, and sheeting. These calender machine are mainly used to press the mixed and refinded rubber mixture or many kinds of plastic ,rubber mixture into uniform-thickness of films, sheets, and plates. Beside , it also can be widely applied to rubber or plastic sheets in single or double sticking operation with textile fabrics

The calendering machine includes two rollers, a motor, reducer, friction gear, distance regulator, thin oil lubrication device, and other main parts/components.

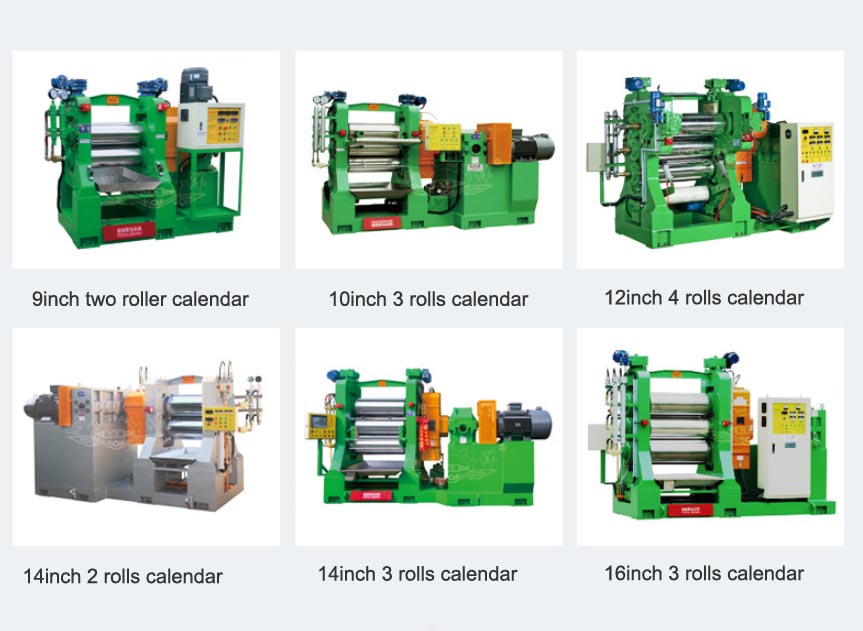

Our calendar machine have different configuration, it is available in two, three, four and five rolls .

Uniform End Result An exclusive method of heating special cylinders allows for close and constant temperature control, which therefore guarantee excellent bonding/lamination and print quality in terms of uniformity . Wide Range Of Operating Temperatures The wide range of temperatures that can be achieved with our custom-built cylinders (ambient temperature up to 225 °C) means that substrates with different properties and requirements can be processed easily. Management Of Substrates During Heat Transfer Printing Process With our extensive experience, we can advise on the best devices for managing and handling materials to be treated (woven fabrics, mono and bi-stretch fabrics, etc.)| Model | SMPCM-6 | SMPCM-8 | SMPCM-10 | SMPCM-12 | SMPCM-14 | SMPCM-16 | SMPCM-18 | SMPCM-22 | |

| Roll Diameter | Inches | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 22 |

| mm | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 550 | |

| Face Width | Inches | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 66 |

| mm | 455 | 610 | 760 | 915 | 1065 | 1220 | 1370 | 1675 | |

| Motor | H.P | 7.5 | 10 | 15 | 30 | 40 | 60 | 100 | 150 |

| R.P.M | 980 | 980 | 980 | 980 | 980 | 980 | 980 | 980 | |

*Silicone Products : Silicone is often used in electronics, medical, food and other industries due to its good high temperature resistance and aging resistance.

*Textiles and Fabrics: In the textile industry, the calendering process can enhance the luster, smoothness, and drape of textile and fabrics, it can increase their dimensional stability and abrasion resistance,it is widely applicable for Bicycle/Auto/Tires/Motorcycles, Single coating/double coating etc. The calendering machine is also suitable for paper, film, nonwoven etc.

*Composite Materials : Used to produce the middle layer of composite materials, such as carbon fiber reinforced plastics (CFRP), etc., and calendering is used to ensure that the layers of materials are tightly combined.

*Plastics and Polymers: The calendering machine are also suitable for production of various plastic and polymer-based products, ideal for polyvinyl chloride (PVC), polyethylene, polypropylene, and other thermoplastic resins ,so that achieve desired surface finishes, thicknesses, and physical properties.

*Floor Tiles: The rolls calendering machine are widely used to manufacture rubber floor tiles, which are widely adapted for playgrounds, gymnasiums, or high-traffic areas. You can cut them to meet custom flooring needs.

*Rainwear:The commingled fabric and rubber polymer result in the formation of raincoats or jackets.

*Luminous Ceilings:The calendering machine are also widely used to form very thin rubber sheeting that you can use in your ceilings.

*Furniture Upholstery: Rubber webbing replaces jute webbing because of unmatchable strength, flexibility, and durability. You can use it on various furniture accessories to make them aesthetically pleasing.

* Double-acting hydraulic cylinders control

* Premium Stainless Steel Construction

<img decoding="async" class="emoji" role="img" draggable="false"

Copyright © 2024 Simptek Machinery