Double-Actings Cylinders Hydraulic Guillotine Bale Cutter SMCM-014

* Double-acting hydraulic cylinders control

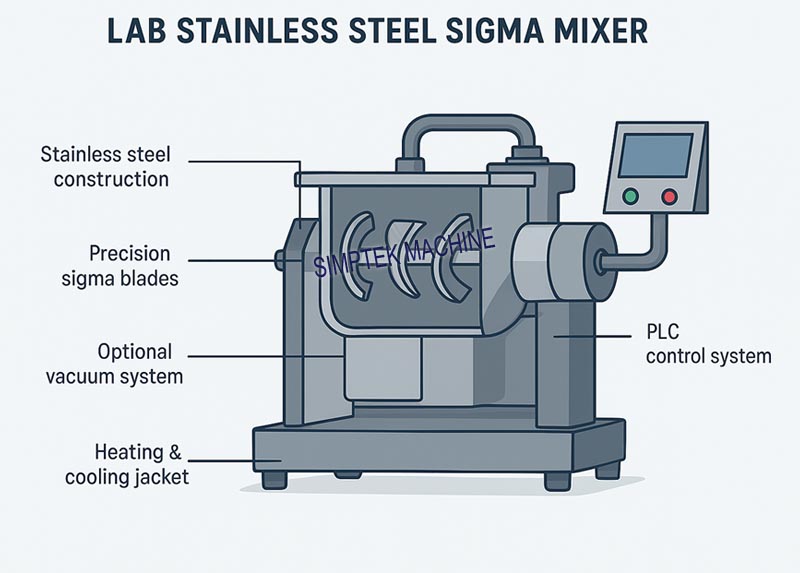

* Premium Stainless Steel Construction – Ensures durability, hygiene, and easy cleaning.

* Precision Sigma Blades – Delivers strong shearing and kneading for high-viscosity materials.

* Optional Vacuum System – Removes air bubbles and improves material quality.

* Heating & Cooling Jacket – Enables temperature-controlled mixing for sensitive compounds.

* Compact Lab-Scale Design – Space-saving structure suitable for laboratory environments.

* PLC Control System – Offers automatic operation, recipe management, and better process control.

The Lab Stainless Steel Vacuum Sigma Kneader is a precision-engineered mixing solution specially designed for laboratory research, product development, and small-batch production. It is mainly used to handle high-viscosity materials such as silicone sealants, adhesives, hot melt, rubber compounds, polymers, inks, and chewing gum etc

Built from high-grade stainless steel, this small-scale sigma kneader machine ensures durability, corrosion resistance, and easy cleaning, thus the precision lab kneader is ideal for handling high-viscosity materials such as polymers, silicone, adhesives, pigments, ceremic , chemical compound and pharmaceutical & food etc.

When this sigma kneader mixer working ,its two counter-rotating sigma blades rotating in different speed in opposite direction , generating intensive shear forces to mix high-viscosity and sticky materials with precision and consistency. This rotating action ensures uniform dispersion of fillers, pigments, plasticizers, or additives.

If equipped with a vacuum system, the vacuum sigma kneader machine machine can effectively remove trapped air and gases during processing, improving product quality and stability.

For these materials required bubble-free compounds, like adhesives, medical-grade silicone, or epoxy paste, the a vacuum system removes trapped air and gases, thus ensuring homogeneous mixing, bubble-free products, and perfect performance of final products.

With PLC control options, with its intelligent automation, and precise control , the small-scale sigma kneader machine can monitor and manager automatically ,including mixing speed, temperature, and timing etc.

This Laboratory kneader mixer offer higher productivity, better quality, and lower operational cost ,it is perfect for R&D labs, universities, material testing centers, and pilot production lines etc.

1. Material Feeding

Raw materials like rubber, silicone,chemical, plastic resins, or adhesives are loaded into the stainless steel mixing chamber.

2. Sigma Blade Mixing

Its two sigma blades inside of the mixing chamber being rotating at different speeds in opposite direction, generating intensive shearing and kneading force to the compound material . This rotating action ensures uniform dispersion of fillers, pigments, plasticizers, or additives,which is critical for product consistency.

3. Temperature Control (Optional)

For temperature-sensitive materials, the jacketed chamber provides heating or cooling via steam, hot oil, or chilled water to maintain precise material temperatures.

4. Vacuum Degassing (Optional)

The vacuum system removes trapped air and gases for bubble-free, improving product quality and stability.

5. Discharge / Extrusion

The handled compound materials are discharged manually through a tilting mechanism , with sigma mixer with extruder ,which automatically push of processed material through a screw conveyor, reducing material loss and shorter discharge times.

| Technical Specifications (Customizable Based on Model) | |

| Parameter | Specification |

| Capacity | 0.5 L – 10 L (Lab Models) |

| Material of Construction | SS304 / SS316 Stainless Steel |

| Mixing Blades | Sigma-shaped blades |

| Drive System | High-torque motor |

| Vacuum Level | Up to -0.095 MPa |

| Temperature Control | Integrated jacket for heating/cooling |

| Control System | Manual / PLC Touch Screen |

| Power Supply | 220V / 380V / Customized |

| Applications | Adhesives, silicone, polymers, pigments, resins, sealants |

(1) Stainless Steel (SS304 / SS316 / SS316L)

The sigma mixer is made of stainless steel material. However ,there are several kinds of stainless steel for option as follow:

SS304 → This is the most ordiary stainless steel, it is mainly suitable for adhesives, inks, and general applications

SS316 → The quality is higher than SS304. Enhanced corrosion resistance due to molybdenum content, ideal for chemical industries

SS316L → The best quality stainless steel material ,also the most expensive one . Low-carbon grade, prevents welding corrosion and is widely used in food, pharma, and medical applications

As we know ,stainless steel material feather high corrosion resistance against chemicals and solvents

*Easy to Clean → Meets sanitary requirements

*Equipped with Vacuum and Jacket System→ Compatible with vacuum and heating/cooling jackets

*Robust Construction→ Long service life, even in harsh environments

This lab-scale stainless steel sigma mixer is ideal for:

* Silicone Compounds – RTV, HTV, LSR mixing

* Adhesives & Sealants – PU adhesives, epoxy pastes, and structural sealants

* Pigments & Masterbatches – High-viscosity colorants and ink pastes

* Polymers & Resins – Rubber compounds, thermoset polymers, and epoxy resins

* Ceramics & Powder Compounds – High-density ceramic slurry preparation

* Pharmaceutical & Food industries

Among all material choices, stainless steel—particularly SS316 and SS316L—is the most commonly used for high-viscosity processing equipment because it offers:

👍Corrosion resistance against aggressive chemicals

👍High mechanical strength for intensive kneading

👍Hygienic surface finishes for food, pharma, and cosmetics

👍Versatility → Suitable for heating, cooling, and vacuum systems

👍Long service life with minimal maintenance

* Double-acting hydraulic cylinders control

<img decoding="async" class="emoji" role="img" draggable="false"

Copyright © 2024 Simptek Machinery