A laboratory hydrualic press machine is a poswerful vulcanizing equipment utilized in the rubber ,plastic and silicone industries for shaping ,forming ,compressing and curing material .

The laboratory plate vulcanizing press machine is a kind of equipment widely used in the production of rubber silicone products, it is mainly used for the vulcanization of rubber products. As we all know ,the process of vulcanization is a key step in rubber processing. By heating and applying pressure, a cross-linked structure is formed between rubber molecules, thereby improving the strength, elasticity, wear resistance and aging resistance of rubber.

This laboratory hydraulic press adopt hydraulic force ,which allows it to generate significant pressure on the material being processed. Due to this function ,this lab hydraulic press equipment is Critical for creating rubber test slabs ,plastic and silicone sheets used in verious products . This hydraulic press machine can mold materials by forcing them into specific shapes or compressing them to achieve uniform thickness and desired shape and characters for futher process.

This compact laboratory hydraulic press machine are constructed by imported KDB high carbon steel solid electric heating plate material, it feature high temperature resistance, corrosion resistance, fast heat transfer, high hardness, not easy to deformation.

This laboratory vulcanizer press equipment is built-in dense point heating wire and high-precision temperature sensor (Japanese platinum resistance temperature sensor) with Japanese RKC(temperature controller) LED temperature controller, it feature with automatic temperature compensation and PID self-tuning function, to ensure temperature balance.

Thse lab rubber vulcanizer fature PLC touchscreen control,which make this equipment easier and convenient to operate, And this vulcanizer press machine is also real-time responsive,like temperature,current ,oil pressure and time are all displayed on the screen. The real-time data of various command swithches and monitoring data are integrated into this high-definition display screen,so that you can transport at any time in your computer .You also can see the dynamic of molding process ,temperature,pre-pressing time and pressuring time ,you can adjust the pressure,heating on this screen.

Our Lab rubber vulcanizing press machine is mainly for rubber vulcanization, thermosetting plastics, and insulation products of pression, it is widely used for R & D in laboratory and college or university lab or institute. It is appliable for rubber(include raw and synthetic rubber ), plastic, silicone material.

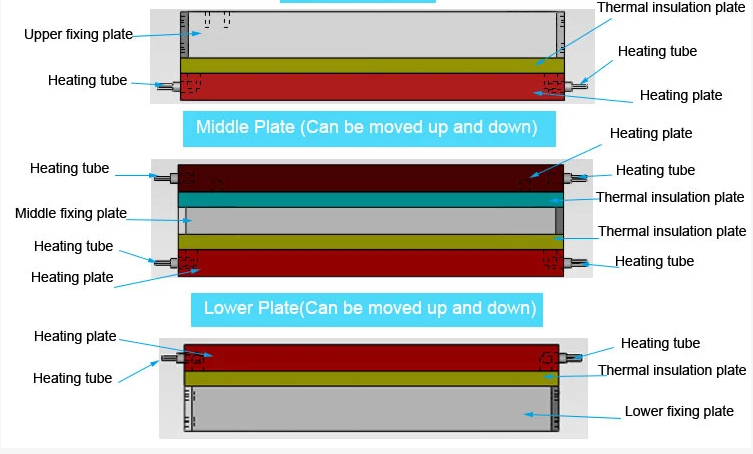

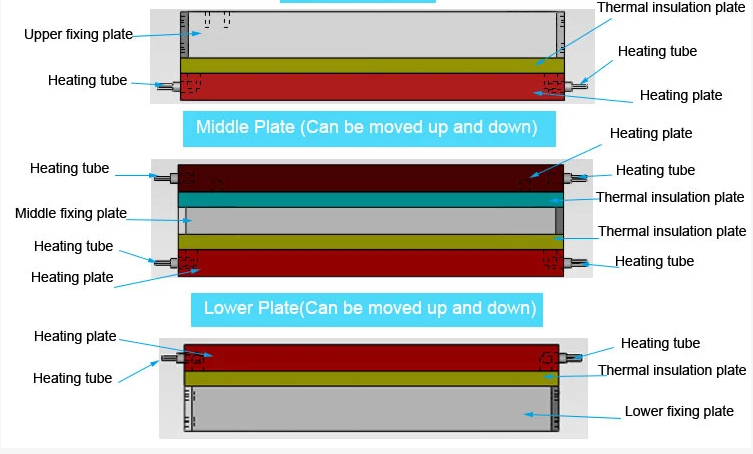

Structure of Hydraulic Press Machine

Technique Parameter

|

SPPL-026 22 T |

SPPL-026 25 T |

SPPL-026 x 2 |

SPPL-026 40 T |

SPPL-026 100 T |

SPPL-026 100 T |

| CLOSING FORCE |

22 T |

25 T |

25/40 T |

40 T |

100 T |

100 T |

| PLATE DIMENSIONS |

350×350 mm |

350×350 mm |

350×350 mm |

350×350 mm |

500×500 mm |

600×800 mm |

| OPENING BETWEEN THE PLATES |

200 mm |

240 mm |

100 mm |

240 mm |

350 mm |

350 mm |

| TEMPERATURE |

200°C / 392°F |

200°C / 392°F |

200°C / 392°F |

200°C / 392°F |

200°C / 392°F |

200°C / 392°F |

| PRESSURE |

250 bar |

250 bar |

250 bar |

250 bar |

250 bar0 |

250 bar |

| OPENING BETWEEN COLUMNS |

240 mm |

240 mm |

100 mm |

240 mm |

350 mm |

350 mm |

| POWER |

4500 W |

4500 W |

7500 W |

4500 W |

9000 W |

9000 W |

| VOLTAGE |

400 V Three-phase |

400 V Three-phase |

400 V Three-phase |

400 V Three-phase |

400 V Three-phase |

400 V Three-phase |

| FREQUENCY |

50/60 Hz |

50/60 Hz |

50/60 Hz |

50/60 Hz |

50/60 Hz |

50/60 Hz |

| MACHINE DIMENSIONS |

670 x 730 x |

965 x 740 x |

965 x 740 x 1640 |

965 x 740 x |

1750 x 1200 x 950 |

1320 x 1100 x 1700 |

| 1170 |

1640 |

1640 |

| WEIGHT |

350 kg |

725 kg |

810 kg |

790 kg |

1790 kg |

2630 kg |

| NOISE LEVEL |

<70 dN (A) |

65 dN (A) |

65 dN (A) |

65 dN (A) |

65 dN (A) |

65 dN (A) |

| Model |

4 Column |

| Capacity |

10T(20T、30T adjustable) |

| Open mold way |

Fully automatic ascending and descending |

| Control Panel |

Chinese,English |

| Temperature |

RT~300℃ |

| Temperature controller |

Japan original import RKC digital temperature controller, LED display button setting input |

| Temperature control accuracy |

±2℃ |

| Temperature signal solid state modulator |

Taiwan brand Solid State Relay English name is Solid State Relay, referred to as SSR |

| Heater |

Taiwan taizhan heater |

| Temperature control mode |

P.I.D self-setting mode with high-precision sensor (Japanese platinum resistance temperature sensor) has automatic temperature compensation function to ensure temperature balance |

| Hydraulic system |

High performance hydraulic system, with automatic pressure compensation function, automatic pressure protection during pressure |

| Timer |

LED digital display 0.1s ~ 99M ~ 9.9h (time adjustable) |

| Electric heating board material |

Imported digital model KDB high carbon steel solid material (high temperature resistance, corrosion, quick thermal reaction, etc.) |

| Hot plate surface |

Chromium plating process |

| Layer qty |

2 layer working area (upper template heating, lower template cooling) |

| Area of electric heating plate |

300×300mm |

| Heating methods |

Electric heating |

| Hot platen |

Two layers of hot pressing plate, one layer with 6 heating pipes x 2 layers, each of which has a power of 400W, and the total power of heating pipes: 4.8kw |

| Cooling way |

Tap water circulation cooling (no pollution and free discharge) |

| Cooling plate area |

300×300mm |

| Spacing of heating plates |

0~70mm |

| Safety device |

Safety cover (outer cover with safety cover and limit switch) |

| castor |

With brake caster, easy to move and fix, bearing more than 500KG |

| Color |

Yellow and white standard or customer specified (paint) |

| Rate of power |

About 9KW |

| Power |

3∮,AC380V weight about 710kg |

| Machine size(W×D×H) |

About 1000×600×1500mm> |

| Accessories |

Stainless steel mirror pressing plate 1set Cleaning wax 1pcs Mold frame: inner frame size150*150mm thickness 1mm 2sets (The size can be customized according to customer requirements) |

Specification

1. Capacity: 10/20/25/30/50/100 tons optional

2. Temperature range: room temperature ~ 300℃,±2℃

3. Temperature controller: LED digital display, key setting input, numerical display output (optional program control type)

4. Heating method: Electrical Heating

5. Cooling method: tap water cooling (connection port of customer’s own water source)

6. Heating time: about 35min at room temperature ~200℃

7. Exhaust frequency: 0 ~ 10 times can be set

8. Gradient pressure: 2 segments

9. Pressure table: 0 ~ 350kg/cm2

10. Working area: double-layer working area with upper heating and lower cooling

11. Area of the electric board: 300×300x60mm; Area of cooling plate: 300*300mmx60mm

12. Distance of pressing plate: 80mm

13. Pressing plate material: SKD chrome-molybdenum alloy

14. Pressing plate surface: HRC60 mirror chrome plating

Power source: 3 wire, AC380V, 20A three-phase five-wire, can be custom as per your needs

Feature of Rubber Vulcanizing Press

* Compact size for laboratory use ,stable temperature and low noise

* Adopt imported digital model KDB high carbon steel solid pressure plate

* Customized design and make plate as per your needs

* With two laminated plates ,the upper plate is heated by electricity and the lower layer is cooled by circulating water

* Equipped with an oil press system and security kick door.

* P.I.D temperature system control

* Available in either Button control or PLC touchscreen model for selection

* East to operate ,accurate temperature and free maintance

How Do Vulcanizing Press Work?

Rubber is often processed with heat and sulfur during production to improve its physical properties. This process is rubber vulcanization,which makes the rubber material stronger and more elastic. From tires and footwear to keypads and gaskets, countless products are made of vulcanized rubber.

The rubber material are placed between two flat heated to a specified temperature . After high temperature and high pressure ,the rubber vulcanization is pressed into the desired shape .

Exposure to heat and sulfur ,the vulcanizing press create new cross-links in the rubber.

Applications

Typical products that can be made on a our hydraulic press machine include:

*Oil seals

*O rings

*Golf balls

*Boots

*Shoes

*Car mats

*Grommets

*Automotive parts

*And many more

Why Need Vulcanizer Press Machine

Vulcanization is a chemical process that enhances the properties of rubber in the rubber vulcanizer press machine . Through the vulcanization press ,the rubber become stronger , more elastic and more durable. Here’s why vulcanization improves rubber:

*Cross-linking: The primary mechanism of vulcanization involves the formation of cross-links between individual polymer chains in the rubber. These cross-links are typically formed by adding additive, sulfur or agents during the heating process.

*Increased Elasticity: The cross-linked network allows rubber to stretch and return to its original shape more effectively. This elasticity is crucial for many applications, such as rubber hoses, shoe soles, toys, erasers, hockey pucks, shock absorbers, conveyor belt , tires and seals, where the material must withstand deformation.

*Improved Strength: The cross-links process also increase the tensile strength of rubber by preventing the polymer chains from sliding past each other under stress. This makes the vulcanized rubber material more resistant to tearing and wearing.

*Enhanced Thermal and Chemical Resistance: The cross-linked make the rubber material better resistance to heat, aging, and various chemicals.

*Reduced Swelling: Vulcanized rubber is less likely to swell when exposed to oils and solvents, which make it more suitable for industrial applications.

Why Chose Us

* Durable Construction : Made of high quality materials ,this hydraulic press machine is built to withstand the demands of heavy-duty industrial use .Its durability guarantees longevity and minimal maintenance , reducing downtime and maximizing productivity .

* User-Friendly Controls : The hydraulic press machine is easy and safe to operate , it allows user to adjust setting and parameters with precision .

* Energy Efficiency : We adopt advanced energy efficient technologies ,which minimize the calender machine energy consumption while maximizing output . It aligns with modern sustainability pracices .

* Versatile Applications : No matter you are in rubber manufacturing , tire production,conveyor belt sheets, flooring sheets or other rubber-related industries , the calender machine is suitable for a wide range of appication .

Request A Quote