Double-Actings Cylinders Hydraulic Guillotine Bale Cutter SMCM-014

* Double-acting hydraulic cylinders control

* Short mixing time ,high efficiency production and good quality rubber compound

* Low labor intensity and low energy consumption.

* An automatic temperature and time control system to provide a 100% mixing result.

* Each batch need about 6~10minutes to output equivalent for 2 open mixing mill

* Pressurized and sealed mixing chamber to provide high mixing performance and prevent the environment.

* Pressurized sealed mixing chamber to ensure the quality of the mixture outside and prevent environmental pollution

* Fillers can be mixed with a variety of materials quickly and easily

* Compounds are produced with exceptional uniformity

* Excellent results even with hard-to-mix materials

* Easy to clean chamber and changing colors

* Suitable for stiring, kneading and dispersion of all kinds of chemical raw materials

* Easy for operation ,easy for changing color ,high quality processed products

Rubber dispersion kneader machine is mainly used for plasticizing and mixing of natural rubber, synthetic rubber, reclaimed rubber and plastics, foaming plastics, and used in mixing of all kinds of low viscosity materials . This rubber dispersion kneader machine feature with small volume, and lower power consumption.

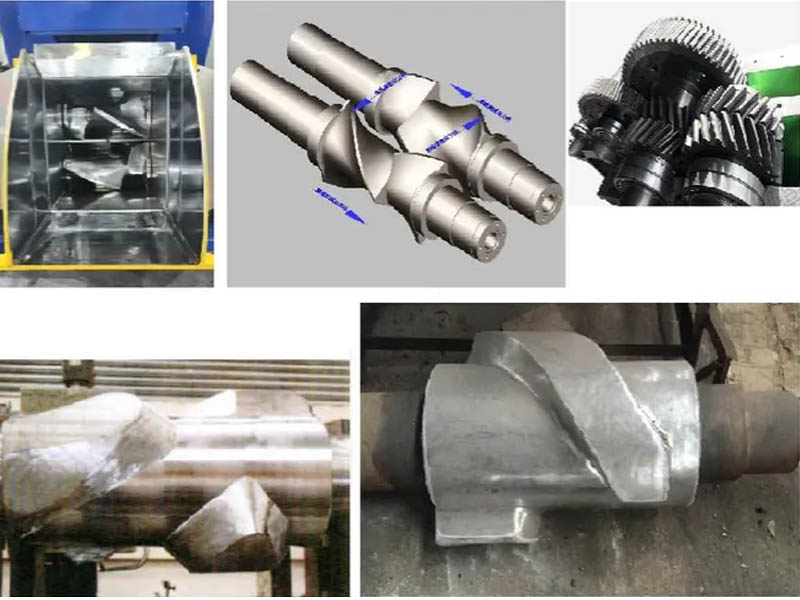

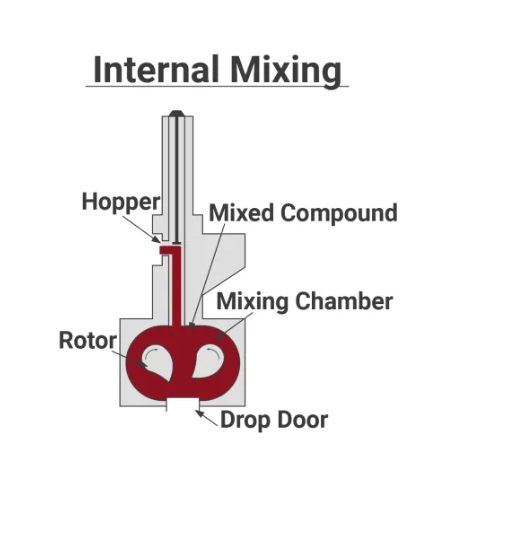

The lab dispersion kneader is mainly consisted of rotor mixing chamber, feeding and pressing device, discharging device, transmission device, sealing device, lubrication system, pneumatic system( Mechanical gravity ) or hydraulic equipment, heating and cooling system and electrical control system.

Our plastic kneader machine are environmental-friendly, high-efficiency and good dispersing effect, it feature with human-orientated design and easy to reload and clean, it has been recognized by factory lab, universities and R&D institutions for recipe researching and small-scale production.

We are direct machine manufacturer , can custom and supply you these machine : Rubber kneader & Dispersion kneader machinery, Internal mixer& Banbury mixer machine , two roll Open mill &Open mixing and other kinds of related machine .

| Model | SPML-014 |

| Volume | 1L, 2L, 3L, 4L, 5L |

| Productivity | 0.6-3kg/time |

| Drive motor | 2.2KW |

| Turning motor | 0.4KW |

| Turning angle | 110° |

| Rotor speed | 0-80r/min |

| Air Compressor | 2.2KW |

| The maximum pressure of the mound | 0.3MPa |

| Discharge method | quick opening |

| Feeding Method | Front materials |

| Water cooling (rubber mixing) | 0.2-0.4MPa |

| Electric heating | 1KW |

| Weight | 600KG |

| Dimension | 1600X700X2000mm |

| Power | 380V AC |

This lab dispersion kneader is specially designed for mixing a variety of materials ranging from low viscosity adhesive to high viscosity polymers ,it feature with small volume, and lower power consumption,the lab kneader equiopment is a high-performance mixing device specially used for for formulation research and small-scale manufacturing.

The dispersion kneader has two blades that rotate toward side to side to cut, mix and blend materials applying different speeds and shear force,which accordingly provide excellent cross mixing of all raw materials.

* Excellent results even with hard-to-mix materials.

* Fillers can be mixed with a variety of materials quickly and easily.

* Compounds are produced with exceptional uniformity.

* Materials are intensively mixed by the pressure lid so that polymers are bonded with fillers more effectively, improving filling ratios

* Unique Jacket Structure Facilitates Low-Temperature Mixing

* The jacket structure helps stabilize and control the material’s temperature so as to prevent thermal deterioration. Material mixing is performed at the optimum temperature.

* The superior cooling effect of the jacket also makes it possible to mix rubber materials and curing agents at low temperatures

* Easy Cleaning and Maintenance

* The rotor surface which contacts the mixed material is made of a wear-resistant alloy.

* Models with a gland packing are also available

| Capacity (L) | 1 | 2 | 3 | 5 | 10 | 15 | 20 | 25 | 35 | 55 | 75 |

| Drive motor (kW) | 2.2 | 5.5 | 5.5 | 7.5 | 15 | 22 | 30 | 37 | 55 | 75 | 110 |

| Rotating motor (kW) | 0.2 | 0.2 | 0.4 | 0.4 | 0.75 | 1 | 1.5 | 1.5 | 2.2 | 3 | 4 |

| Turning angle | 110° | 110° | 110° | 110° | 110° | 110° | 110° | 110° | 140° | 140° | 140° |

| Air Compressor (kW) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 7.5 |

| Cooling water (MPa) | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 |

| Electric heating (kW) | 0.7 | 0.8 | 1.2 | 1.8 | 1.9 | 2.1 | 4 | 4.5 | 10 | 15 | 18 |

| Weight (kg) | 800 | 900 | 1000 | 1200 | 2300 | 2800 | 4500 | 5000 | 6500 | 7800 | 10800 |

Safety – Supplied complete with electrical equipment to operate the blades and tilting mechanism, these laboratory kneaders are built according to applicable health and safety regulations.

Design - The Simptek Lab Kneaders are available in laboratory and industrial production with capacities ranging from 1 to 150 liters, the design are available in vacuum design, jacketing, control systems.

* Enhanced productivity : Increase your production efficiency with this high-capacity kneader, reducing processing time and enhancing overall output.

* Consistent Quality :Achieve unparalleled consistency in rubber compounds ,satisfying the most stringent quality standards with every batch.

* Versatility : Suitable for a wide range of rubber formulations and applications , also applied for diverse industry needs .

* Reliable Performance : Experience reliable and precise mixing ,ensuring uniform dispersion and superior product quality .

* Double-acting hydraulic cylinders control

* Premium Stainless Steel Construction

<img decoding="async" class="emoji" role="img" draggable="false"

Copyright © 2024 Simptek Machinery