Double-Actings Cylinders Hydraulic Guillotine Bale Cutter SMCM-014

* Double-acting hydraulic cylinders control

* ‘U’ shaped trough for improved access and effective cleaning

* Full SUS304 stainless steel construction throughout

* Fully welded blade designs

* Dust tight lids with quick release closure

* Batch size based on 65% of Blender volume.

* Bearing mounted on lanterns out of the Mixing zone to avoid Cross-contamination.

* Feeding through a charging port mounted on top of the blender.

* Reduced Material handling due to side discharge facility of processed materials.

* Continuous Ribbon design for complete discharge of the finished product.

* Variable frequency drive for fine-tuning the Shear energy at different stages of Blending.

* Working capacity: from 3 cubic feet up to 515 cubic feet

| MODEL | SMPRM150 | SMPRM500 | SMPRM1000 | SMPRM2000 | SMPRM3000 | SMPRM4000 | SMPRM5000 | SMPRM7500 |

| GROSS CAP. (LTRS) | 150 | 500 | 1000 | 2000 | 3000 | 4000 | 5000 | 7500 |

| WORKING CAP. (LTRS) | 100 | 325 | 650 | 1300 | 2000 | 2600 | 3250 | 5000 |

| DIMENSION IN MM (L*W*H) | 1600*800*1250 | 1800*800*1300 | 2500*1000*1500 | 3500*1200*1750 | 4000*1500*2000 | 4500*1800*2000 | 4950*1800*2000 | 5450*2000*2000 |

| RPM | 15/30 | 15/30 | 15/30 | 15/30 | 15/30 | 15/30 | 15/30 | 15/30 |

| HP | 3/5 | 5/5 | 7.5/10 | 10/15 | 20/25 | 25/30 | 30/40 | 40/50 |

The horizontal ribbon blender workds with an inner ribbon that carries the material from the center to the outside and an outer ribbon that moves the material from two sides to the center. When moving the materials , the two ribbons are joined a rotating direction. The horizontal ribbon blender allow you to mix in less time while getting a better result

Mixing Process:The mixing process begins when the materials are loaded into the mixer container. Once the container is loaded, the motor is turned on and the paddles begin to rotate.The shaft is driven by a motor that is actually connect with paddles ,which are precisely pitched to move material both radially and axially in opposite directions.

Mixing Time: The amount of mixing time rely on the type and volume of materials being mixed. However, most paddle mixers have a set mixing time that can be adjusted depending on the application.

The horizontal ribbon blender workds with an inner ribbon that carries the material from the center to the outside and an outer ribbon that moves the material from two sides to the center. When moving the materials , the two ribbons are joined a rotating direction. The horizontal ribbon blender allow you to mix in less time while getting a better result

Mixing Process:The mixing process begins when the materials are loaded into the mixer container. Once the container is loaded, the motor is turned on and the paddles begin to rotate.The shaft is driven by a motor that is actually connect with paddles ,which are precisely pitched to move material both radially and axially in opposite directions.

Mixing Time: The amount of mixing time rely on the type and volume of materials being mixed. However, most paddle mixers have a set mixing time that can be adjusted depending on the application.

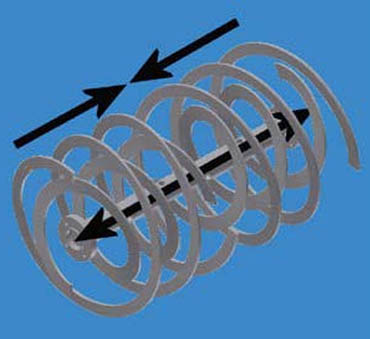

Double-Ribbon Agitator

The double-ribbon blender agitator is valued for its thorough mixing. It consists of an inner and an outer ribbon providing counter-directional flow while keeping the product in constant motion throughout the vessel. The inner ribbons move materials toward the ends of the ribbon blender whereas the outer ribbons move material back toward the center discharge of the ribbon blender.

Double-Ribbon Agitator

The double-ribbon blender agitator is valued for its thorough mixing. It consists of an inner and an outer ribbon providing counter-directional flow while keeping the product in constant motion throughout the vessel. The inner ribbons move materials toward the ends of the ribbon blender whereas the outer ribbons move material back toward the center discharge of the ribbon blender.

Paddle-Ribbon Agitator

The paddle-ribbon agitator combines inner ribbons with outer paddles. The paddle-ribbon blender is especially well suited for fragile, heat sensitive products. While maintaining counter-directional flow, the outer paddles minimize pinch points at the wall thus introducing less frictional heat than a continuous outer ribbon.

Paddle-Ribbon Agitator

The paddle-ribbon agitator combines inner ribbons with outer paddles. The paddle-ribbon blender is especially well suited for fragile, heat sensitive products. While maintaining counter-directional flow, the outer paddles minimize pinch points at the wall thus introducing less frictional heat than a continuous outer ribbon.

* Double-acting hydraulic cylinders control

* Premium Stainless Steel Construction

<img decoding="async" class="emoji" role="img" draggable="false"

Copyright © 2024 Simptek Machinery